A 360-degree look at resin conveying systems: types, operation, economics, design, installation, components and controls.

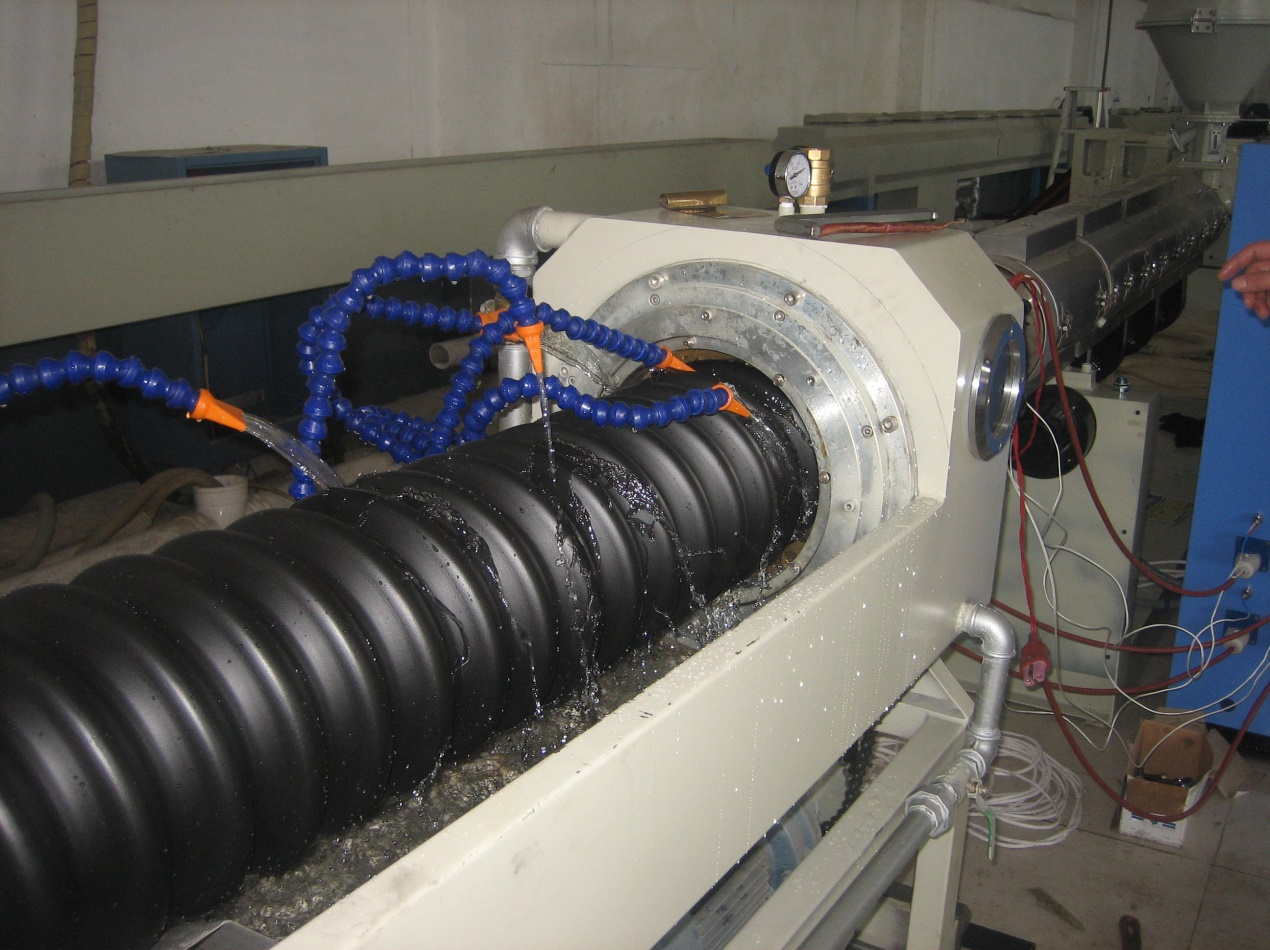

This Knowledge Center provides an overview of resin moisture and the drying process, including information on the best drying practices for your manufacturing facility. Pvc Flexible Pipe Machine

Everything you need to know about plastics compounding technology—from feeding solutions to application profiles and expert advice.

Combat the skilled labor shortage using this comprehensive resource to train your own plastics processing experts.

Deep dive into the basics of blending versus dosing, controls, maintenance, process integration and more.

This Knowledge Center provides an overview of the considerations needed to understand the purchase, operation, and maintenance of a process cooling system.

Learn about sustainable scrap reprocessing—this resource offers a deep dive into everything from granulator types and options, to service tips, videos and technical articles.

While price initiatives for PE and PVC were underway, resin prices had rollover potential for first two months of 2024, perhaps with the exception of PET.

Flat-to-downward trajectory for at least this month.

A mixed bag, though prices likely to be down if not flat for all this month.

Trajectory is generally flat-to-down for all commodity resins.

Flat-to-down trajectory underway for fourth quarter for commodity resins.

Generally, a bottoming-out appears to be the projected pricing trajectory.

Resin drying is a crucial, but often-misunderstood area. This collection includes details on why and what you need to dry, how to specify a dryer, and best practices.

Take a deep dive into all of the various aspects of part quoting to ensure you’ve got all the bases—as in costs—covered before preparing your customer’s quote for services.

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankand and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

In this collection, which is part one of a series representing some of John’s finest work, we present you with five articles that we think you will refer to time and again as you look to solve problems, cut cycle times and improve the quality of the parts you mold.

Gifted with extraordinary technical know how and an authoritative yet plain English writing style, in this collection of articles Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

In this three-part collection, veteran molder and moldmaker Jim Fattori brings to bear his 40+ years of on-the-job experience and provides molders his “from the trenches” perspective on on the why, where and how of venting injection molds. Take the trial-and-error out of the molding venting process.

Mike Sepe has authored more than 25 ANTEC papers and more than 250 articles illustrating the importance of this interdisciplanary approach. In this collection, we present some of his best work during the years he has been contributing for Plastics Technology Magazine.

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Mold maintenance is critical, and with this collection of content we’ve bundled some of the very best advice we’ve published on repairing, maintaining, evaluating and even hanging molds on injection molding machines.

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

Medical-component specialist LightningCath has carved a niche meeting the needs of small to medium-sized entrepreneurs with complex catheter designs … quickly.

Plastics Technology is closing in on its 70th anniversary. Here are some of Editorial Director Jim Callari’s observations to commemorate the occasion.

As with everything else, there are pros and cons, but more of the former. They provide processors higher rates while decreasing the temperature of the extrudate while enabling downgauging.

The drop in plastics activity appears to be driven by a return to accelerated contraction for three closely connected components — new orders, production and backlog.

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Pairing external big picture training with internal job-specific instruction can help your process technicians meet quality expectations as well as production targets.

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

Flat-to-downward trajectory for at least this month.

Topping five other entries in voting by fellow molders, the Ultradent team talks about their Hot Shots sweep.

Serendipitous Learning Opportunities at PTXPO Underscore the Value of Being Present.

Introduced by Zeiger and Spark Industries at the PTXPO, the nozzle is designed for maximum heat transfer and uniformity with a continuous taper for self cleaning.

Ultradent's entry of its Umbrella cheek retractor took home the awards for Technical Sophistication and Achievement in Economics and Efficiency at PTXPO.

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

Shibaura discusses the upcoming Plastics Technology Expo (PTXPO) March 28-30

Competition will invite participants to help reshape life cycle management in plastics.

Sign up to attend North America’s leading trade show for plastics.

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Ahead of the first NPE since 2018, PLASTICS announced that its triennial show will stay in Orlando and early May for ’27, ’30 and ’33.

New features of NPE2024 aim to “bring the whole plastics ecosystem together to innovate, collaborate and share findings.”

Hundreds of tons of demonstration products will be created at NPE2024 next spring. Commercial Plastics Recycling strives to recycle all of it.

Mixed in among thought leaders from leading suppliers to injection molders and mold makers at the 2023 Molding and MoldMaking conferences will be molders and toolmakers themselves.

After successfully introducing a combined conference for moldmakers and injection molders in 2022, Plastics Technology and MoldMaking Technology are once again joining forces for a tooling/molding two-for-one.

Multiple speakers at Molding 2023 will address the ways simulation can impact material substitution decisions, process profitability and simplification of mold design.

When, how, what and why to automate — leading robotics suppliers and forward-thinking moldmakers will share their insights on automating manufacturing at collocated event.

As self-imposed and government-issued sustainability mandates approach, injection molders reimagine their operations.

August 29-30 in Minneapolis all things injection molding and moldmaking will be happening at the Hyatt Regency — check out who’s speaking on what topics today.

Get your clicking finger in shape and sign up for all that we have in store for you in 2023.

Molding 2023 to take place Aug. 29-30 in Minnesota; Extrusion 2023 slated for Oct. 10-12 in Indiana.

Key technologies — such as multicolor molding, film molding and PUR overmolding for both exterior and interior applications — are at the forefront of this transformation. Join this webinar to explore the vast potential of eMobility in molding large components — including those with fiber reinforcements — thereby driving the need for large injection molding cells with a clamping force of up to 11,000 tons. You will also gain insight into Engel's innovative two-stage process, a solution for future recycling processes. This webinar will provide an in-depth overview of challenging applications, production concepts and best practices, including: BMW iX front panel production cell Smart rear panels concept based on IMD and 2C molding Sustainability concepts based on two-stage process Large tonnage equipment for battery moldings

In today's manufacturing environment, robust processes that meet strict industry and regulatory standards are essential. With the advent of servo-driven ultrasonic welding technology, enhancing product quality and maintaining consistency has become remarkably effortless. Discover the fundamentals of ultrasonic welding, delve into vital components within these systems, explore how servo-driven ultrasonic welding enhances weld quality via advanced control features and gain insights into optimizing your assemblies for welding in these high-performing machines. Join Dukane to unlock the potential of ultrasonic welding in modern manufacturing for plastic devices and components. Agenda: Fundamentals of ultrasonic welding Key components in an ultrasonic welding system Using servo-driven ultrasonic systems to control your welding process Designing your parts and components for servo-controlled ultrasonic welding

This webinar will help you make informed decisions to confirm the equipment access stairs in your facility are OSHA compliant and meet the highest standards of safety and ergonomics. Agenda: Identifying opportunities to increase safety in the work place Utilizing space saving stairways Ensuring code compliance for equipment access

4.0, EUROMAP, OPC, OLE, QC, DSN, SQL, VNC, MES, ERP, FTP, CMS, SPI — are you confused by all buzzwords being tossed around in the plastics industry? Not convinced the data collection is necessary? Or are you unsure of how it could be implemented and improve your molding processes? Wittmann has been on the cutting edge of the data collection push for nearly 20 years. In this webinar, take a step back from the idea of the manufacturing facility of the future and discuss what you can do today to improve your process. Using readily-available technology, Wittmann can help reduce downtime, limit scrap and wasted material, and predict required maintenance. Let the experts at Wittmann help you understand: what data can be collected, what that data can be used for, what systems are used, and how to implement them. Agenda: Demystifying the terminology Tracking the material flow and lot information through the material handling system The data available from various auxiliary equipment, such as: dryers, blenders, mold temperature controls and robots Automating the process through changes in the data collected at the machines during production Adding visualization to increase productivity

Learn how targeted, modular, dosing and blending solutions — covering powders, granules, regrinds and liquids — provide plastics processors of all kinds with best-in-class accurate dosing while delivering significant raw material savings and ensuring highest quality. Agenda: Introduction to Movacolor Blending in plastics applications Movacolor feeding and dosing technology Hybrid blending to combine high material throughput and dosing accuracy

This presentation will explore the in-situ polyurethane (PU) overmolding of injection-molded and composite parts, allowing for direct out-of-mold class "A" surfaces. KraussMaffei will review the process and equipment required. It will also discuss tooling types currently available for PU systems for this process. KraussMaffei will compare the pros and cons of this technology over currently-available coating and painting systems. Agenda: Introduction and evolution of the ColorForm technology Overview of the ColorForm process Equipment required Tooling and PU systems Benefits of the system compared to typical spray-applied coatings Pros and cons of the technology

The global plastics industry has been navigating through what is arguably the most volatile period in decades. Unprecedented amounts of new production capacity are scheduled to start in North America, Europe, and China in the near term and compete for demand during a period of economic challenges. How will trade flows shift? Will this lead to regional cost disparities and rationalization? Energy transition and sustainability targets continue transforming the plastics market and increasing the competitive landscape. As the market evolves, what impact will new technology, policy, regulation, the growing role of chemicals versus fuel and other factors have on industry restructuring and business models? At GPS 2024, leading global experts will come together to discuss pivotal impacts and initiatives shaping the plastics industry. Join us and participants from across the globe to gain the latest insight and deep analysis as you connect with your peers and industry professionals. This year’s conference will explore the theme Disruptive Global Dynamics Reshaping Plastics and include a full day workshop focused on the Global Plastics Business and Plastics Transition to Circularity, 1.5 days of expert content and numerous networking functions.

Every three years, leaders from almost every major industry gather at NPE to advance their businesses through innovations in plastics. The largest plastics trade show in the Americas, NPE offers six technology zones, keynote speakers, workshops and opportunities to build partnerships.

The 3D Printing Workshop @ NPE2024 – The Plastics Show, is an immersive, half-day workshop focused on the emerging possibilities for part production via 3D printing and additive manufacturing. Presented by Additive Manufacturing Media, Plastics Technology and MoldMaking Technology, the 3D Printing Workshop will build upon a successful model first introduced at IMTS 2014. Attendees will benefit from a program focused on practical applications of 3D technologies related to plastics processing. This event will conclude with a 3D Printing Industry Reception sponsored by Additive Manufacturing Media.

The Society Plastics Engineers (SPE) Extrusion Division and the SPE Eastern New England Section will co-host the Screw Design Conference-Topcon on June 19-20, 2024 @ UMass Lowell in Lowell, MA. This highly technical program will focus upon screw design principles for single and twin screw extruders with wide ranging topics relating to screw designs for feeding, melting, mixing, venting and pumping plastics products and parts. Areas of focus will include screw designs for melt temperature and gel management, gel minimization, bioplastics, recycled materials and foaming. In addition to the technical sessions, a tour of the UMass Lowel Plastics Processing Laboratories will be integrated into Day 2 of the event. This program is not just for screw designers, but to help anyone responsible for any type of extrusion operation to evaluate existing extrusion equipment; and also to prepare for future projects. Price to attend: Less than $1000! Registrations will be accepted in early 2024. Call for papers – To be considered to give a presentation, please submit a talk title and abstract on or before December 15 to: Technical Chair: Eldridge M. Mount III, e-mail emmount@msn.com Corporate sponsorships - A limited # of corporate sponsorships (15) are available on a 1st come basis. Included is a 6’ tabletop display (must fit on table), denotation in all promotional activities, and 1 no charge registration. To become a sponsor contact: Charlie Martin, Leistritz Extrusion, e-mail cmartin@leistritz-extrusion.com, cell 973-650 3137 General information: A reception on Day 1 and a tabletop display area will allow the attendees to meet and discuss state-of-the-art screw technologies with industry experts. The SPE Extrusion Division will issue a “Screw Design Certificate” to all participants who have attended the program. Students are encouraged to attend and will receive a discounted rate. For additional information contact: Program Chair: Karen Xiao, Macro Engineering, KXiao@macroeng.com

Debuting in 2010, the Parts Cleaning Conference is the leading and most trusted manufacturing and industrial parts cleaning forum focused solely on delivering quality technical information in the specialized field of machined parts cleansing. Providing guidance and training to understand the recognized sets of standards for industrial cleaning, every year the Conference showcases industry experts who present educational sessions on the latest and most pressing topics affecting manufacturing facilities today. Discover all that the 2022 Parts Cleaning Conference has to offer!

Presented by Additive Manufacturing Media, Plastics Technology and MoldMaking Technology, the 3D Printing Workshop at IMTS 2024 is a chance for job shops to learn the emerging possibilities for part production via 3D printing and additive manufacturing. First introduced at IMTS 2014, this workshop has helped hundreds of manufacturing professionals expand their additive capabilities.

Tandem extrusion of PS is still the standard technology, but new materials options and equipment technology are emerging.

Tandem extrusion lines are still preferred for PS foam processing because they provide very high output rate and more desirable cellular structure.

In tandem low-density foam extrusion, the two connected extruders have quite different functions. The primary extruder (top) works to melt and homogeneously mix the materials, including additives and reclaimed pellets. The secondary extruder cools down the melt prior to foaming in order to optimize melt strength and strain-hardening behavior.

The primary extruder in a tandem line is frequently equipped with a pineapple mixing section (or a Saxton mixer) to improve distributive mixing

Cell population density is proportional to the number of impurities incorporated in the melt. Talc is the most commonly used cell nucleating agent for foaming but must be used sparingly. Pressure-drop rate also plays an important role in determining cell population density. Image: C. B. Park et al., Polymer Engineering Science (1995)

Melt-temperature control is crucial to maximize the foam expansion ratio. If it’s too high, considerable gas loss results; too low, and the material may crystallize or solidify before sufficient expansion. Image: H. E. Naguib et al., Journal of Applied Polymer Science (2003)

An experimental comparison of high-temperature durability between conventional PLA foam and Macro’s heat-resistant PLA foam shows no major deformation of the heat-resistant PLA foam after filling with boiling water.

Low-density foams made of commodity polymers have countless applications, and most processors produce foamed sheet from tandem extrusion lines. But quite a few wonder why tandem foam lines are required in the first place. These lines are more complicated and difficult to run, not to mention more expensive, than a single-extruder foaming system.

Moreover, in some cases a tandem extrusion line isn’t altogether necessary to extrude low-density foams. For instance, low-density polystyrene (PS) foam sheet can be produced on a single foam extruder at output rates of about 600 lb/hr. So why is it possible for PS, and why can’t other thermoplastics be foamed similarly? To answer these questions, two matters need to be considered.

First of all, the most critical factor affecting the stable foaming process for producing high-quality foams with low density is the rheological characteristics of the polymers used. The rheology is related to crystallization behavior, the molecular structure, and the molecular weight. PS is a polymer with excellent foaming characteristics for several reasons. It’s an amorphous resin whose melt viscosity is relatively less sensitive to melt temperature than is the case with semi-crystalline polymers. This means that the melt-strength distribution cannot be as broad as the melt-temperature distribution.

PS is based on addition polymerization of styrene monomer, and as a result it has a weight-average molecular weight ranging from 150,000 to about 400,000 g/mol (higher than condensation polymers such as PET or PLA). This means that PS has relatively higher viscosity and melt strength at normal processing temperature (230 C, 446 F) and foaming temperature (120-140 C, 248-284 F). What’s more, PS has a bulky benzene ring as a branch to the backbone of the polymer molecule, which is favorable to forming higher entanglement density of molecular chains, even at high temperature. This feature is also believed to contribute to strain-hardening behavior during the biaxial elongation.

Since PS does not crystallize, there is no concern about a drastic viscosity hike, especially while the melt is being cooled down to reach the optimum melt temperature for achieving the best-quality foam.

Because of these material characteristics, PS can be foamed with relative ease, even on an unsophisticated single-screw extruder that provides less uniform melt-temperature distribution at the end of the secondary extruder. Given that PS gives relatively higher closed-cell content than other commodity polymers (regardless of the level of sophistication of the foaming equipment), it is safe to say that PS is one of the best polymers for various foam processes.

Yet despite its ease of processing, tandem extrusion lines are still preferred for PS foam processing because they provide very high output rate and more desirable cellular structure (see Fig. 1). With one extruder it is very difficult to achieve a high cooling capacity, due to significantly limited residence time.

The second critical factor contributing to the quality of the final foam is the foaming equipment. In a typical tandem low-density foam extrusion line (Fig. 2), the two connected extruders have quite different functions. The primary extruder works to melt and homogeneously mix the materials, including additives and reclaimed pellets. Also, since physical blowing agent is injected into the primary extruder, the screw in the extruder plays an important role in dispersing the blowing agent into extremely fine droplets.

These droplets must be dispersed in the melt in such a way that the interfacial area is maximized, so that a homogenous phase of the blowing agent/polymer solution is obtained in the shortest time possible. In the primary extruder, a pineapple mixing section or a Saxton mixer (Fig. 3) is used frequently to improve distributive mixing.

For safety reasons, the primary screw should have a blister ring, which acts as a melt seal, right before the injection port of the blowing agent. This prevents the flammable hydrocarbon blowing agent from flowing back to the hopper or feeding zone. The blowing-agent-laden melt would go through a crossover melt pipe from the primary to the secondary extruder.

The secondary extruder is usually called a cooling extruder because that is its basic function in the process. The melt is cooled down to optimal temperature to maximize the melt strength and the strain-hardening behavior at the foam expansion stage. The optimum melt temperature varies, depending upon the content of blowing agent dissolved in the melt and the original onset temperature of crystallization or solidification during cooling.

For example, PS dissolved with 5% isobutane should be cooled from 220 C (428 F) down to around 135 C (275 F). This is a typical condition for producing PS foam sheet used for disposable food packaging such as meat trays and clamshells. During the dramatic reduction of melt temperature, the viscosity of the melt substantially increases, especially at the end of the secondary extruder. It is quite challenging to achieve uniform melt-temperature distribution, which directly affects the melt-strength uniformity.

In the case of semi-crystalline polymers, crystallization in the barrel of the cooling extruder can happen and induce a melt-pressure hike, particularly when the melt temperature goes down too much, which makes the foaming process much more difficult to control. Depending upon the solubility of the blowing agent used, the melt pressure should be maintained above the solubility pressure of the blowing agent in such a way that the blowing agent can stay completely dissolved in the melt. When the cooled molten polymer dissolved with blowing agents approaches the die-lip exit, cell nucleation takes place due to thermodynamic instability triggered by reduced pressure.

Basically cell-population density is proportional to the number of impurities incorporated in the melt. Talc is the most commonly used cell nucleating agent for various foaming processes. The typical range of talc content is 0.3-2% by weight for optimal cellular structure and expansion ratio. Adding too much talc might result in high open-cell content due to extremely low cell-wall thickness, which is attributable to excessively high cell-population density. Pressure-drop rate also plays an important role in determining cell-population density (Fig. 4).

Once the cells are generated in the nucleation step, they keep growing until the cell pressure goes down and reaches the ambient pressure. This is called a cell-growth stage, where both solubility and diffusion rate of the blowing agent affect the cell growth rate in the expanding foam. For instance carbon dioxide (CO2) alone is nearly impossible to use for production of low-density foam sheet using an annular die, because of severe corrugation on the surface of the foamed sheet. This is why butane or pentane is frequently used for manufacturing PS or PP foam sheet. CO2 is more appropriate for high-density or medium-density foam having numerous fine cells, considering its higher cell-nucleating power than hydrocarbon blowing agents.

During the cell-growth stage, the foam goes through dramatic quenching because of adiabatic expansion and brisk heat absorption during vaporization of the blowing agent. In order to maximize the foam expansion ratio, melt-temperature control is very important because too high a melt temperature can lead to considerable gas loss due to cell rupture and coalescence, and too low melt temperature can make melt crystallize or solidify before sufficient expansion, as indicated in Fig. 5.

Cooling air is often applied to the surface of foam exiting the die, which is intended to form a very thin, solid skin layer on the foam surface for higher gloss because the appearance of the foam is commercially important.

THE PLA ALTERNATIVE While PS foaming has been widely used for decades, of late it has been placed under the environmental microscope. Whether the claims being made by environmentalists—and the bans that have followed in many cities—are based on “sound science” is not the point. Truth is, many processors are looking at more “environmentally friendly” options, with polylactic acid (PLA) being highest on the list.

Since it’s a biobased polymer, PLA is compostable, and, at less than $1/lb in North America as of this writing, is regarded as one of the most reasonable alternatives to PS foam. But foaming PLA is no easy processing feat. As already noted, PLA is a condensation polymer with lower molecular weight than PS, so it has intrinsically lower viscosity and melt strength. This makes the rheological properties of PLA quite sensitive to melt temperature.

As a result, to foam PLA, chain extenders must be added to increase the molecular weight to boost viscosity and melt strength. Even though the chain extender is compounded with the PLA, it is still difficult to get high-quality PLA foam with high expansion ratio—as well as high closed-cell content—using conventional tandem PS foam extruders. This is because in most cases the conventional tandem foam extruders for PS are incapable of providing excellent melt-temperature uniformity. In particular, cell opening on the cell walls can take place due to local weak spots in extensional viscosity as the cell-wall thickness gets thinner and thinner during the cell-growth stage.

Since PLA is a semi-crystalline polymer and its viscosity is quite low and sensitive to melt temperature, it is extremely difficult to properly foam PLA for low-density products. Moreover the crystallization-induced viscosity hike at a low temperature range plays a role in narrowing the foaming process window. Thus these uncooperative attributes of PLA resin inevitably require a more advanced tandem foam extruder that has innovative screw and extruder designs for a reactive extrusion process for foaming PLA. For this reason, only a few foam manufacturing companies could succeed in commercializing low-density PLA foam for disposable packaging around the world.

The currently commercialized PLA foam still has a couple of constraints in actual applications. Firstly, low-density PLA foam has inadequate heat resistance for high-temperature applications. PLA foam is significantly deformed when put in contact with boiling water or hot foods. Secondly, the FDA has not approved the use of PLA foam having the chain extender in direct contact with hot food or water. This is because of concerns that the epoxy-based chain-extender molecules could leach into the hot-filled contents.

As a result, the application of current PLA foam sheet is limited to only low-temperature packaging like trays for meat, fish, vegetables, and fruits. These two drawbacks have been delaying the practical replacement of traditional PS foam with compostable PLA foam.

Recently Macro Engineering and Technology Inc. rolled out an innovative tandem foam extrusion line that is capable of producing 16 times expanded PLA foam sheet with the aid of advanced screw and equipment design. In addition, Macro invented a patent-pending new technology to overcome the two critical disadvantages of conventional PLA foam. Figure 6 shows the experimental results comparing boiling-water resistance between conventional PLA foam and Macro’s heat-resistant PLA foam. It is clear that no major deformation of the foam is shown for the heat-resistant PLA foam sheet.

All things considered, compostable PLA foam as a renewable alternative packaging is projected to attract gradually more and more attention in foam packaging markets across the world.

ABOUT THE AUTHOR: DR. RICHARD LEE

Dr. Richard (Eungkee) Lee received his BSc, MSc (Seoul National University, South Korea) and PhD (University of Toronto) in Polymer Science and Extrusion Foaming Process. Currently he is a R&D project manager of Macro Engineering and Technology Inc., Mississauga, Ont., in charge of developing extrusion foam lines for PLA, PP, PS, and other polymers. Contact: (905) 507-9000; rlee@macroeng.com; macroeng.com.

Thin-gauge sheet production presents some unique challenges to the extrusion operator, including the following set of 10 commonly encountered considerations

If you don’t baseline your extruder, then how are you going to set realistic expectations for its performance? Here's how to get going.

Both the power-law coefficient and the consistency index must be considered to calculate viscosity.

Depending on what you are trying to accomplish, molecular orientation can have a positive or negative impact on your part. Here’s how to control it.

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Pe Film Recycling Line Plastics Technology covers technical and business Information for Plastics Processors in Injection Molding, Extrusion, Blow Molding, Plastic Additives, Compounding, Plastic Materials, and Resin Pricing. Learn More